This is a project to restore a John Deere 1940 model H farm tractor that belonged to Ryan Rutledge's great grandfather James Carpenter.Web site manager: Eugene (Gene) D. Johnson, Ryan's grandfather.

446 Trinity Drive, Allen, TX 75002

469-675-1316

This web page was initiated November 17, 2004, and last up-dated February 12, 2006.

Here is the young farmer boy now:

The following pictures represent the "before" condition of the tractor:

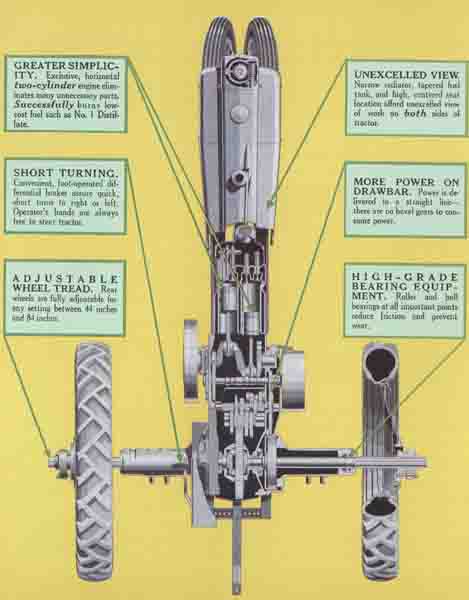

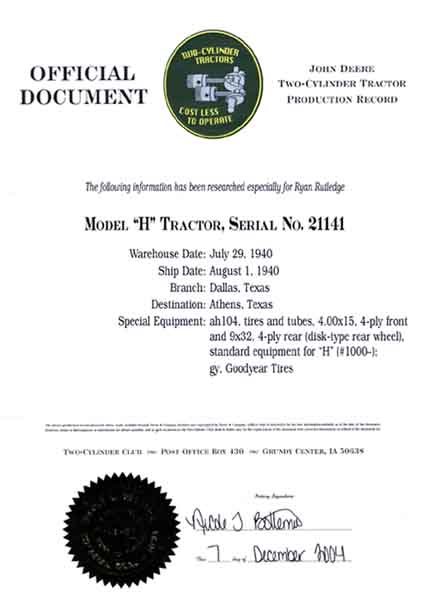

The John Deere (JD) model H tractor was introduced in 1939, starting with serial number 1000. The tractor being restored has serial number 21141, so, it was the 20,141th model H built.

The communication I have had, via the internet and by telephone, with others who have knowledge of this tractor tell me that during the first couple of years of a new tractor release, JD made undocumented changes on the production line that may not be reflected in the parts and service manuals. Their only comment on this was to check to see that what is on the tractor matches the parts and service manual. BTW, I was able to order these manuals (owners and parts) from JD on a CD. I have also ordered an Implement and Tractor (IT) service manual via eBay.

Mr. Carpenter acquired the tractor in about 1970 as payment for some work preformed for the previous tractor owner. He used it occasionally to plow land for a spring garden.

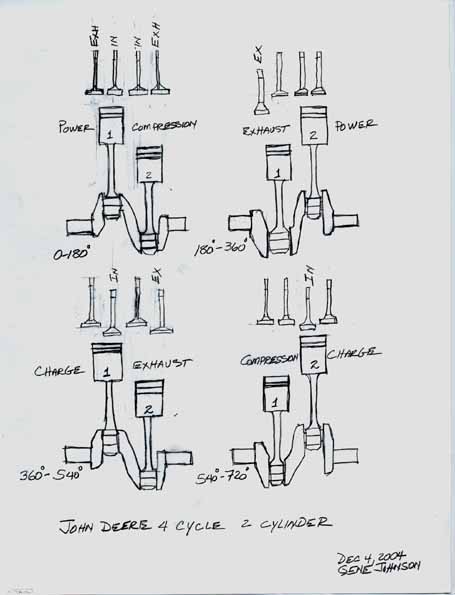

My first inspection of the tractor showed that the engine turned over easily with the clutch disengaged by manually rotating the flywheel toward the front (counter clockwise). While doing this, I was able to feel the resistance of the compression cycle indicating that there was at least some compression. This is an indication of the condition of the piston rings and valves.

I observed that there was an automotive engine coil and condenser wired into the magneto. This modification was added on later and not the original electrical circuit. It was probably done to save the cost of a magneto repair and/or the need to keep the tractor working during a critical period in the cycle of farming. .

The early farm tractors and also cars used magnetos to provide an electrical charge to the sparkplugs. The magneto consists of a coil, a capacitor, and a set of points to open and close the circuit. When the points are opened as the engine is hand cranked, the capacitor will discharge to the plug firing the air/fuel mixture in the cylinder.

Today’s tractors and cars use an electric starting system powered by a battery and a started motor. This option was available in 1939 however the option was not put on this tractor.

Last Monday (November 8) I sent the magneto to a shop Iowa for repair but have now learned that it cannot be repaired but must be replaced. Fortunately there is a company that still makes a similar version that will work so I have ordered the new one.

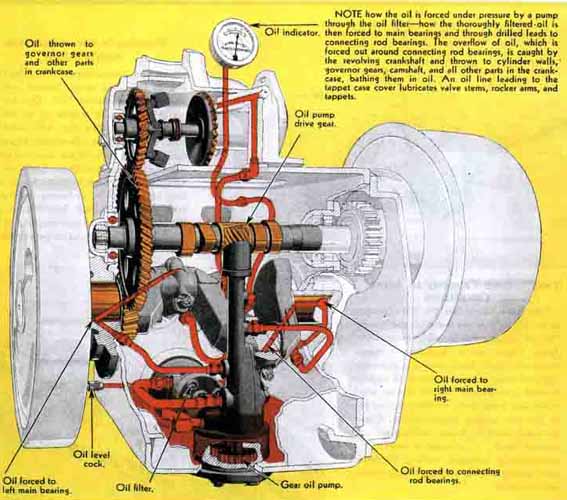

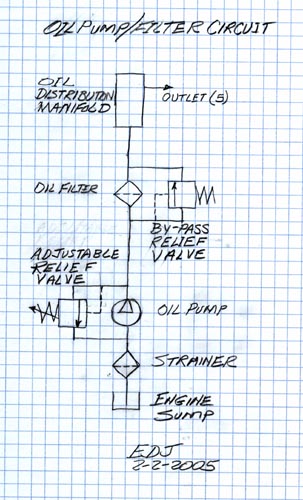

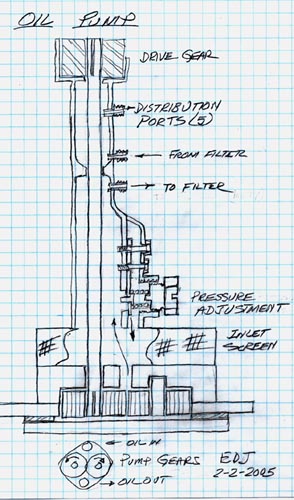

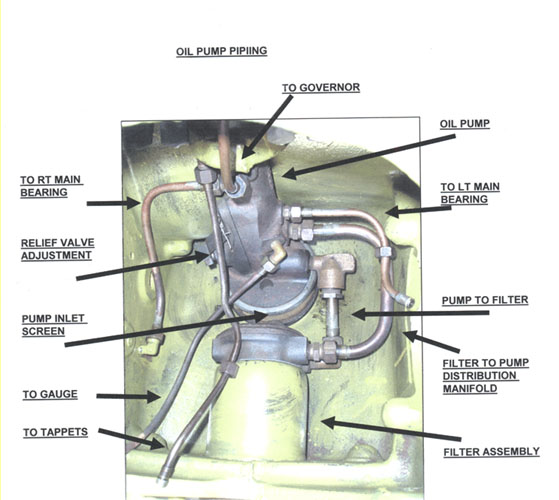

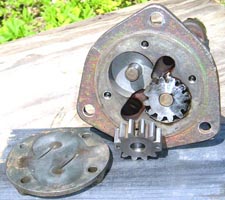

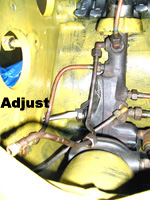

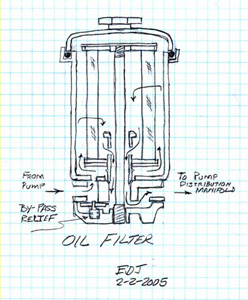

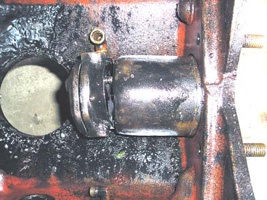

I have also ordered an engine oil filter and have purchased SAE 40 weight non-detergent oil. I have decided to use heavier weight oil (SAE 40) to compensate for engine wear. The operation manual calls for SAE 30 weight oil. I was able to find non-detergent oil which is what would have been used originally. The detergent oils came about in more recent years with the high performance automotive engines that run at high temperatures and operate at several thousand revolutions per minute (RPM). The operating speed for this tractor at full load is only 1400 RPM (1700 RPM can be achieved using the foot pedal for higher road speed). Plus, adding detergent oil now would loosen all the sludge that has accumulated over the years and quickly plug the filter. At this point, this sludge should not be free to get into the working parts.

I also notice that there is no water pump or thermostat. The cooling water is circulated via convection due to the heat difference across the radiator. John Deere advertised this as “Thermosyphon” cooling. The engine operating temperature is maintained by the operator using mechanical shutters on the radiator. Desired operating temberature is 190 degrees Fahrenheit. Although, it doesn’t look like this tractor is equipped with shutters. They probably weren’t necessary in Texas.

The engine air filter is an oil bath design using engine oil.

December 3, 2004

The following is an update on progress of getting the tractor started so it can be driven into the garage.

to do list: